The 2026 sailing season is here. Many of you are considering purchasing a

new Corsair trimaran or a new Dragonfly trimaran or a pre-owned trimaran.

Where do you set your priorities?

There is so much to learn about a specific trimaran that it can become overwhelming. Are there a people who will help you train? Where do you plan on sailing? Do you like flexibility as much as performance? Who will be sailing with you? What kind of experience do they have as crew? Is there a strong owner community in my area? How soon can I receive one? Then who supports my choice? If something breaks who do you turn to? The list goes on and on. Our 180 Marine trimaran experts are here to help.

Setting your priorities with our team helps to organize and prioritize your options. (e.g., trailering importance, cruising nights per year, budget, crew size, displacement, sail area ratios, estimated resale values, wait times, years or months?, expensive repairs, owner community…

To illustrate this we’ll start by comparing a Corsair 970 and a Dragonfly 28 trimaran based on acquisition cost. Prices vary from model to model, but think about these issues as you bring your purchase criteria to our team of advisors.

Below is a clear, owner-focused comparison of the upsides of buying a new Dragonfly trimaran versus buying a new Corsair 970, framed around real-world ownership, not brochure specs.

Dragonfly 28

Dragonflys are generally considered premium boats with high-end construction

Choose 2026 Dragonfly 28 if you want: More cabin comfort and long-term cruising capability

PROS

• High potential performance and upwind ability

• Aesthetics & Styling: Sleek, European lines; premium look/feel.

• Stability & Feel at Speed: Very stable and confidence-inspiring in rough conditions.

• Interior Space & Comfort: Large, comfortable cabin volume.

• Folding/Marina Handling: Excellent folding system — fast, precise, reduces slip costs.

• Performance (Speed) Typically high potential speed, especially downwind.

Dragonfly 28

CONS

• Lead Time for New: Often 2 years (very few pre-owned come on the market)

• U.S. Support Network: Very good service/dealer network, but not everywhere.

• Maintenance Simplicity: More complex systems may mean specialized care.

• Service and support in North America: Fewer experienced service yards and dealers.

• Trailer-ability: Trailerable but heavier/wider; requires bigger tow setup/logistics.

• Complex folding system: Repairs may require specialized knowledge.

• Resale Appeal (Premium Market): Stronger in markets that value premium design and build — may hold value well among enthusiasts.

• You’re paying a deposit now, but must wait for your order to be completed.

• Your funds are not liquid. (assets or investments that cannot be quickly and easily converted into cash at the current fair market price.)

• Delay in owning & enjoying your boat.

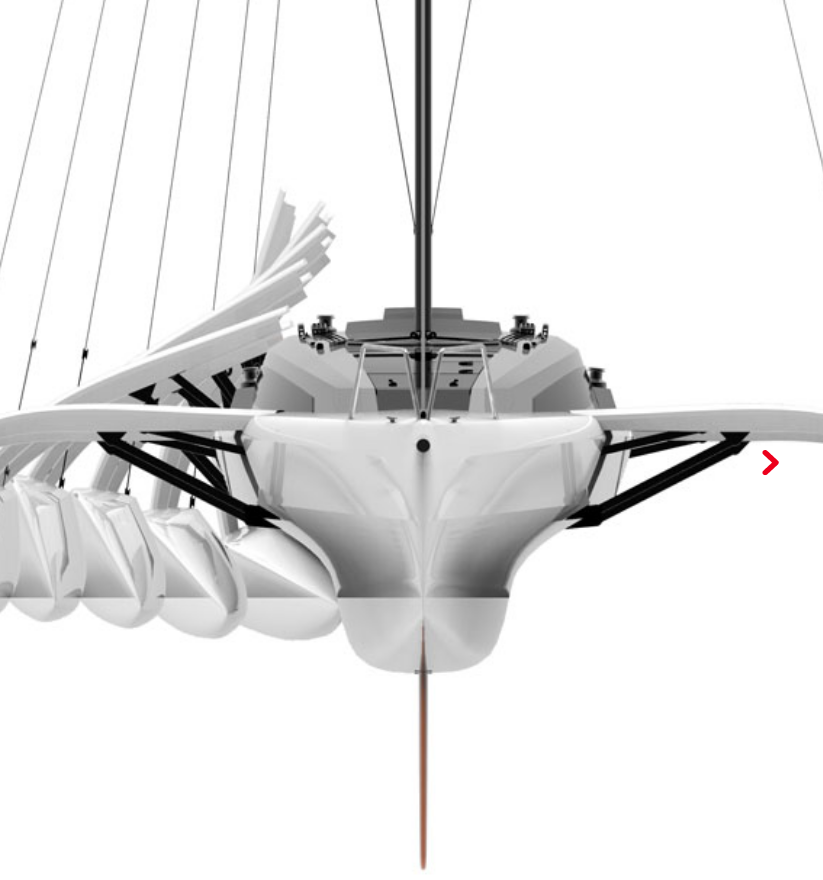

Corsair 970

Choose a 2026 Corsair 970 if you want: Excellent performance for its class.

PROS

• High-volume floats have been designed with additional buoyancy for sailing performance, giving the Corsair 970 great stability and comfort.

• Refined Interior: The saloon boasts a sleek, white GRP liner for a clean, modern finish.

• Expanded Galley: Includes additional drawers and ample storage for long journeys.

• Private Enclosed Head: Offers added convenience and privacy.

• The Corsair 970 has a remarkably low heel, feels light, and is easy to manage on the helm.

• Quick and efficient on the water. At the same time, the added interior space ensures your time spent onboard is comfortable and enjoyable.

• With Corsair trimaran, availability is generally strong and you often get delivery within 5-6 months, not years.

• Lower acquisition cost (even when well-optioned)

• Faster delivery and lower acquisition price

• Simple folding system → easier service & fewer failure points

• Excellent U.S. parts availability and dealer support

• Highly trailerable (one of its strongest advantages)

• Strong resale market in North America

• Repairs are commonly understood by local yards, and easier DIY maintenance

A more forgiving learning curve and service network.

CONS

• More Spartan Amenities: More basic finishes and hardware than premium boats.

• Impact: Less “home-like” at anchor or under sail.

• Limited carrying capacity and storage. But good headroom throughout.

• May require more active trimming to extract top performance.

• Light and responsive hulls mean a livelier ride in chop and stronger seas.

• Trimaran hull designs offer less capacity for heavy cruising gear. (weight matters)

If you’re weighing specific models (e.g., Dragonfly 28 vs Corsair 970) or want help estimating real delivery costs in 2026/27/28, we can share a detailed cost comparison with quotes and tariff estimates. Just let us know.

Richard Allen / Founder / Expert Multihull Sailor / Ownership Coach!